Corona virus is being perceived as a huge threat to mankind. We are witnessing a global lock down with certain restrictions in place due to this pandemic. As a result of this, many small businesses have been impacted with no/low sales and a complete breakdown of the supply chain management. This has led to many of the basic requirements used in our day to day lives, for example toilet paper, running out of stock in some countries. Hence it is important and critical to manage the supply chain between the factories and the stores.

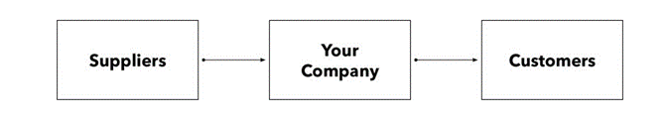

What is supply chain management?

Supply chain management is the management of the flow of goods and services and includes all processes that transform raw materials into final products.

Impact on supply chain management:

Normally, there is a regular flow of raw materials and components from one place to its destination to ensure production of the customer’s desired products. However, if there is a break or disruption in this product transformation process, the management should step in to plan and ensure that the production of the final product does not get impacted.

Many businesses rely on the raw materials or parts which are imported from some other country. The outbreak of COVID-19 has impacted the flow of products and services from the point of production to the point of consumption because of non-availability of either workers or adequate transportation system. For example, if a company were to rely on or purchase products from areas tagged as RED ZONE (a highly affected containment area), it is going to have a massive impact on the production capacity. Similarly, many small businesses in the red zones have also shut down and this has hit the entire production life cycle leading to economic slowdown in many countries.

Some big manufacturers have also stopped production at their factories, because of the non-availability of raw materials & intermediates from various cities/countries. It is high time that the supply chain Managers take appropriate alternative steps to get the raw materials / components from alternate vendors to maintain continuity of business and products, thereby retaining their company’s customers. By not doing so, Organizations run the risk of losing their customers to competition.

Here are a few news clippings which demonstrate the impact of corona viral outbreak on supply chain management:

- Fiat Chrysler Automobiles NV announced a few months back that “it is temporarily halting production at a car factory in Serbia because it couldn’t get parts from China.” This is the first time that a European carmaker has stopped its production.

- Most of the Apple products like iPhone and other products are made in China. The temporary break in production will impact its retail stores as this would result in reduced supply of iPhone’s globally

- Hyundai has totally thirteen plants worldwide, including seven in South Korea. A news brief from Hyundai states that “it has decided to suspend its production lines from operating at its plants in Korea”. This was because the viral outbreak had disrupted the auto part wiring harness and other electrical parts that were being produced and imported from China. The company has reviewed alternate options to continue its production of vehicles. During February this year, the company restarted its production as they managed to import these spare parts from South East Asia

- In addition, ships used for trade/exchange of goods are avoiding to dock at China, which has led to a huge impact on trade and supply chain. Both air and ship cargo suspension has led to huge losses, sharp dip in Sales revenue and a break in supply chain.

- Routing of refrigerator cargo containers containing chicken from United States to China are being diverted to Hong Kong, South Korea, Taiwan and Vietnam. This has resulted in frozen and poultry meat getting spoiled because of the non-availability of electrical outlets. This has resulted in an artificial scarcity in the market apart from revenue loss to the shippers.

- Some pharmaceutical industries which depend on raw material to come from COVID affected areas, have now downsized their production as even transportation is not possible resulting in breakdown of the supply chain

As part of business ethics, it is mandatory for all businesses to deliver the promised quality products to their consumers on time, and hence there is a need to have a good supply chain management. Here are a few recommended measures that would be helpful to ensure an uninterrupted supply chain.

Approach alternative sources for inventories

- Analyse, shortlist and approach alternate/multiple sources for availability of inventories. In the event of inventory not being available from option A, every manufacturing firm should keep alternate options of B or C who could be approached for basic raw materials/ components.

Periodic check on inventory levels of raw materials

- Taking stock of availability of the finished goods, spare parts/ raw material, recycling of defective products etc., should be carried out as often as possible depending on the production cycle to ensure that production does not stop at any given point in time. This will improve your customer’s trust and credibility in your Company and your product. This will also help you to create a good relationship with the consumer of your product, in addition to assisting you in planning and building a healthy pipeline to forecast immediate/future needs of your product.

Assess your production capacity

- Based on the next three to six months orders, adequate raw material required should be available so as to ensure that the production cycle/schedule runs optimally. This will hedge you from any slowdown in supply chain management and will not impact your production line. In addition, please ensure that adequate safety measures are in place for each of your employees. It would be prudent to do periodic health check of your employees so that they don’t absent themselves or fall ill during critical delivery schedules.

Distribution Capacity

- Timely transportation is essential to ensure that goods/products are delivered on time and meet the committed timelines promised to your customers. During such a pandemic outbreak like the one we are witnessing now, the cost to transport the products may significantly go up due to the non-availability of transport. To overcome such challenges, you would need to collaborate with multiple transport agents that you could fall back on, to transport your products, in case of need.

By taking some of the measures recommended above, you could minimize the economic loss that you are likely to incur on account of outbreak of such an unforeseen pandemic. With some of the countries talking about reduction in number of Covid infections, there are newspaper reports that mention about several small and medium size businesses having commenced production. This should hopefully help them to recover the losses, that arose on account of the disruption of supply chain and slowdown in trade /economy.

Supply chain is likely to come back to normalcy once the vaccine or drug is discovered to completely eradicate the dreadful corona virus. Once it gets eradicated, we believe that everything will be back to normal like before and the demand for the product / service, including the underlying supply chain will be work efficiently.

Share this blog :

Leave a Reply